Magnetic iron selection

Magnetic drums

The magnetic drum selects the steel scrap (waste) from a vertical material flow. The advantage is that selection and delivery are continuous thereby, and the installation height is low.

- Magnetic drums

- Magnetic material

- Non-magnetic material

Feeding to the magnetic drum is done by a vibrating feeder or conveyor belt. The drum shell rotates around a stationary magnetic field. The fed material flows over the surface of the drum. All materials that are not affected by the magnet will fall freely from the magnet, while ferrous metals are captured by the shell and held on the surface of the drum, and then dropped outside the magnetic field, where they are collected.

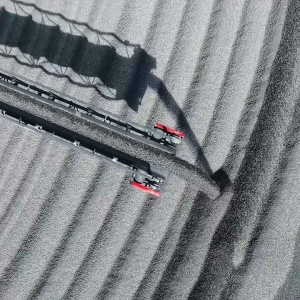

Magnetic belts

In the case of continuous material handling - from conveyor belts - the best solution for selecting ferrous metals is to use magnetic belts. Depending on how strong magnetic field is required, permanent or electromagnets are used.

At the right height

Permanent magnetic belts are usually located 250-300 mm above the conveyor belt that transports the material. However, it depends on the transported material, the layer thickness, the belt width and the speed of transport.

Electromagnet

For installation heights above 400 mm, we recommend the installation of an electromagnetic belt. Its operating principle is the same as that of a belt containing permanent magnet, but the magnetic field is generated by electric current, not by the permanent magnet. Part of the electric current conducted into the magnet is transformed into heat, which thus reduces the magnetic field. A cold electromagnet is approximately 20% stronger than a heated one, therefore, cooling the magnet is very important for the safe operation.

Advantages

Unlike block magnets, the "caught" pieces of iron are continuously removed from the magnet of the magnetic belts by the rubber belt, consequently it cleans the magnet thereby, and then the selected iron waste falls in one point. It is suitable for selecting a larger amount of iron than the block magnet.

Inline / Crossline

It can be installed both longitudinally and crosswise, depending on the technological possibilities. The magnet attracts unalloyed iron, low-alloyed and some high-alloyed steels, and cast irons, but does not attract valuable, corrosion-resistant steels with a high Ni and Cr content, and other non-ferrous metals such as copper and aluminium.