NIR Optical Sorters

Recycling has become an essential industry in the circular economy. Reducing ecological damage and saving precious and valuable resources is a particularly important task for us. For recycling, however, the purity of the waste types must be ensured, for which the optical sorter is an excellent help.

(NIR)

NIR (near infrared) refers to a spectrum in the range between 950 and 2190 nm, which is invisible to humans. Each material has a well-identifiable light reflection curve, a so-called spectral fingerprint. The control system of the sorter examines these ‘fingerprints’ with the help of a hyperspectral imaging camera, and distinguishes them from each another. Even the smallest differences in the chemical composition of the detected substances can be evaluated.

- PET

- PE

- PP

- PET+PVC

- PET+PP

- PET+PS

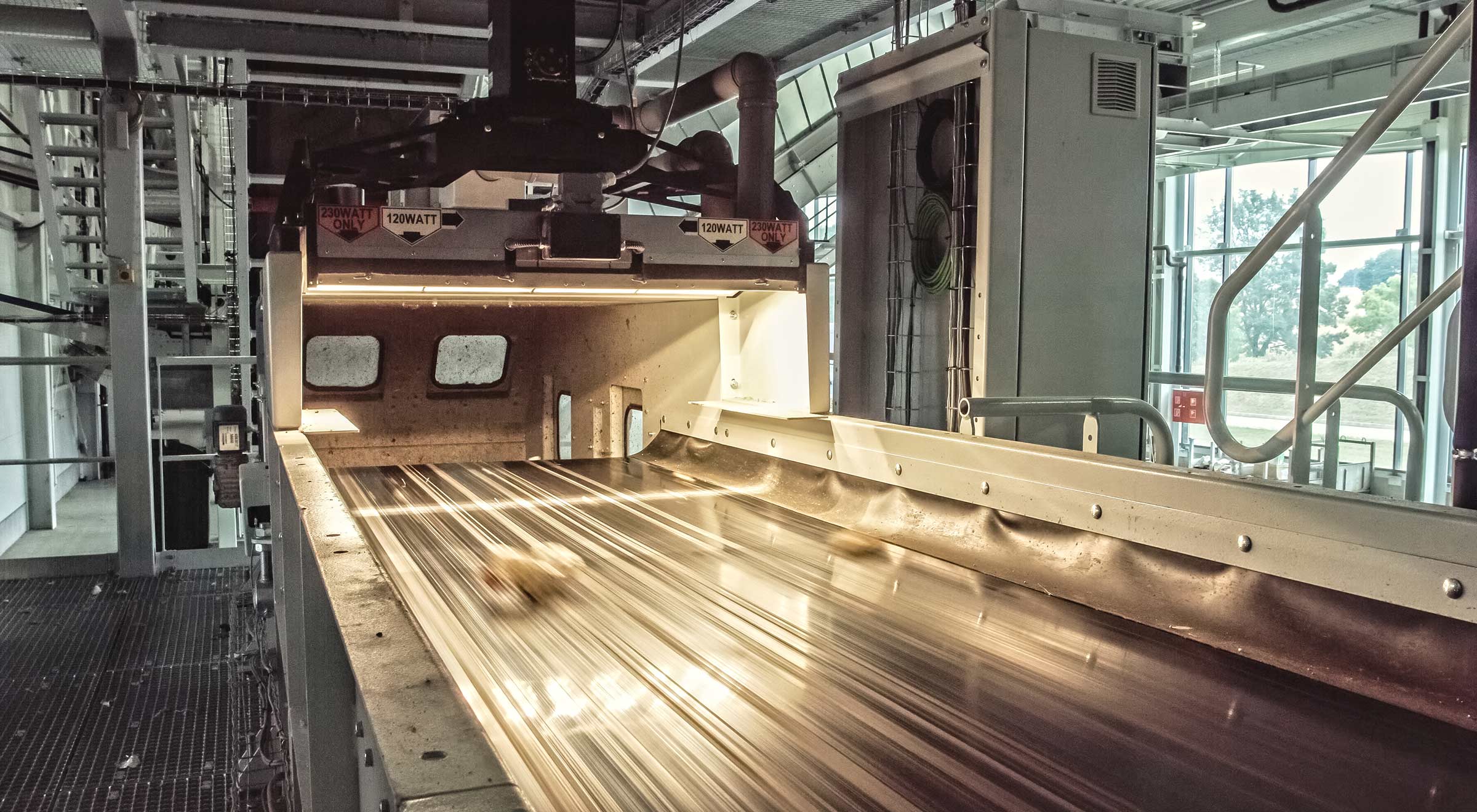

Lightning-fast operation

The materials, spread out optimally, reach the detection area via a fast-moving conveyor belt. Once they have arrived, sensors ‘scan’ the material flow based on the colour, shape and type of material. The control unit activates the pneumatic unit with precise timing and positioning, and that unit removes impurities and contaminants from the material flow.

Versatile use

The optical sorters are universal; they sort different types of waste, such as PET, PP, PE, PS, PVC, PA, paper, cardboard, wood, TETRA, textiles or glass accurately and efficiently. The detected particle size range is 3-300 mm. Our sorting systems are always prepared for the given field of application.

Plug&Play design

The modular design allows for the combination of different sorting widths. It can be operated and configured quickly via the touchscreen with easy navigation. It can be controlled on-site and remotely through a TCP/IP network.

It is our expert colleagues’ pleasure to assist you.